If I were to say, “I sent you a package – it'll be there Thursday” what do you picture? Was it a mailperson knocking on your door holding a box? That makes sense, boxes have been the standard packing method for consumer products for years. While there are specific circumstances where a box might be the ideal solution for your packing needs, do not underestimate the impact a mailer can have on you and your customers.

Mailers are an excellent opportunity to save time and money while not sacrificing payload safety, customization options, or the environment. While it is not a cure-all, mailers should be a big part of your pack out process. As you read further, we encourage you to think outside the box.

Boxes vs. Mailers

So how do mailers stack up against their stackable box counterparts? Do they really offer anything significant over boxes?

- 3Xs faster pack out than boxes: Just load, seal, and label! Standard RSC (regular slotted carton) boxes require set up, flap folding, bottom sealing, loading, top sealing, and labeling. Thats twice as many steps to arrive at the same goal and twice as many opportunities to make an error.

- Dimensional Weight Savings: Most mailers measure less than 1,738 square inches which avoids USPS dimensional weight charges resulting in a $0.50 to $10.00 per package savings.

- 80% Shipping Weight Reduction: Mailers weigh an average of 80% less than boxes. A 1lb weight reduction can result in a $0.50 to $3.50 shipping cost reduction.

- Lower Material Costs: Mailers packing the same size products cost 20% to 60% less than standard shipping boxes.

- Reduce Waste: On average, boxes are packed with 10% more packaging materials than what is needed for protection. As a result, they are 30% larger than they should be.

Mailers are also available in several different shapes, sizes, colors, and customization options allowing you to perfectly pair your mailers to your unique products and brand. If you are still worried about your products arriving safely, mailers again have you covered with padded and cushioned interior options.

What About Sustainability?

Let’s face it, using fewer packing materials means less waste and less of a negative impact on the world around us. But we can do better - we can lessen our footprint even further by using mailers designed with sustainability in mind.

JiffyLite Bubble Mailers

Material: Paper outer shell with 3/16” bubble cushioning interior.

Sustainability: 100% Recycled paper & 10% PCW Recycled Poly.

Sizes: 11 Standard Sizes.

Custom Printing: Standard 1 & 2 Color

Jiffy Padded Mailers

Material: Paper fiber cushioning contained by durable kraft paper interior and exterior liners.

Sustainability: 100% Recycled Fibers.

Sizes: 12 Standard Sizes.

Custom Printing: Standard 1 & 2 Color.

TuffGard Mailers

Material: Heavy duty poly outer shell with 3/16” bubble cushioning interior.

Sustainability: 12% Post-Consumer Waste (PCW).

Sizes: 13 Standard Sizes.

Custom Printing: Standard 1 Color.

Mailers are an excellent packaging method for small to medium size businesses that want to get e-commerce goods to their customers while reducing shipping & labor costs, as well as their negative impact on the environment. (I mean who wants to be the company hurting the planet?) But what if you are a large company who sends out thousands of packages daily?

PriorityPak® Automated Packaging System

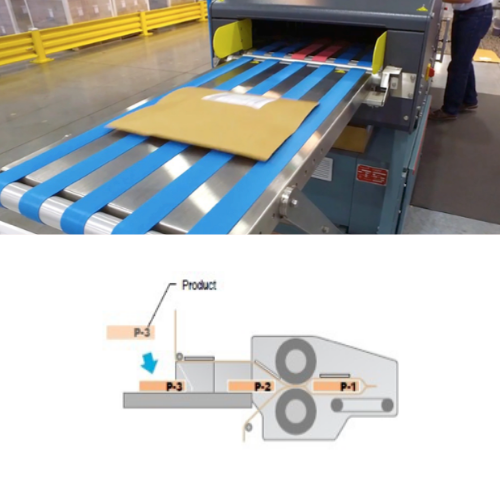

PriorityPak® is a high-speed, semi-automated packaging machine utilizing protective cohesive packaging material.

Features, Advantages, & Benefits

- Protective: Encapsulates products in Cold Seal® cohesive-coated packaging

- Efficient: Creates 12-15 packages a minute for a considerable enhanced throughput

- Adjusts to Volume: Sensors adapt to fluctuating volume & variable packaging requirements

- Labor Savings: One machine can reduce labor cost by 4 to 12 times with no overtime

- Material Reduction: Eliminates boxes, internal cushioning, & tape

- Reduced Shipping Cost: Conforms to products, reducing dimensional weight shipping costs

- Versatile: Can be used at pack stations or be seamlessly integrated into existing packaging lines

- Sustainable: PriorityWrap® Rigid Board materials are made from 50% recycled materials & are curbside recyclable

- Enhanced Customer Experience: Custom color printing, easy tear strips, & perforations available

The PriorityPak® sandwiches a product between two rigid cohesive paper materials and is pressure sealed, labeled, & cut to size; creating a highly customized mailer that then gets fed into a shipping bin. The mailers that are used with the PriorityPak® are the PriorityWrap® Rigid Board and the PriorityWrap® Bubble Laminate.

PriorityWrap® Rigid Board

- Protective rigid construction

- 100% curb side recyclable

- Widths: 9.5” (750’L), 12’(625’L), 15” & 18” (500’L).

- Strengths: 69#, 56#, 42#, 33#

- Openings: perforated, notched, tear tape

- Custom sizes & printing available

PriorityWrap® Rigid Board is a strong, rigid, 100% curbside recyclable, paper fiber material lined with a cohesive film that sticks to itself but not the product being protected. It comes in many standard widths and strengths with several easy open or custom width options. It protects the product by locking it in place to avoid internal shifting or movement, while the rigid material provides superior tear resistance and corner/edge impact protection.

PriorityWrap® Bubble Laminate

- Lightweight to save on postage

- Cushioned with a 3/16” Bubble Wrap liner

- Available in film width sizes 12”, 16” & 18”

- Custom sizes & printing available

PriorityWrap® Bubble Laminate is a lightweight, bubble wrap lined mailer, great for items requiring a bit more cushion. Much like its counterpart it comes in several standard sizes with custom size and printing options available.