Folding Cartons are paperboard containers or displays that offer high quality visuals through the use of printing, stamping, embossing or coating. They are incredibly versatile and can be made with varying shapes, styles, designs, finishes, thicknesses and materials to help you differentiate your product from competitors. The cartons are also 100% recyclable, making them extremely environmentally-friendly as well as cost-effective.

Interested in a Folding Carton solution?

Popular Folding Carton Styles

Tuck Top (TT)

Straight Tuck End (STE)

Seal End

Rolled End Tuck Top (RETT)

Reverse Tuck End (RTE)

Header Cards

Display / Dispenser

Beers Tray

Auto Bottom (AB)

Snap Lock Bottom (SLB)

Material Options

- SBS (Solid Bleached Sulphate) - White, virgin 2-sided with highest quality appearance

- CCNB (Clay Coated Newsback) - Smooth white exterior, off-white/grayish back

- CCWB (Clay Coated Whiteback) - White front, white/off-white back

- CCKB (Clay Coated Kraft Back) - White top, kraft back made for heavy duty application

- Bending Chip (Grayish/Brown) - Rigid 100% Recycled, coarser surface made for heavy duty

- Blister - Laminating a semi-rigid material to folding carton header board for retail applications

Printing Methods

Offset

Defined: Also called "lithography", for mass-production printing in which the images on metal plates are transferred (offset) to rubber rollers for printing on paper or board stock.

Application: For high volume runs requiring photo quality (tight registration, high-graphic) at a reasonable cost.

Flexographic

Defined: also called "surface printing", where rubber or plastic plates print directly to material.

Application: For looser registration, less ink coverage & more simplistic print projects such as industrial applications where costs need to weigh equally against quality.

Digital

Defined: Process of transferring a digital computer-based image to print through laser or inkjet equipment

Application: Small runs or projects requiring continual changes to art layouts.

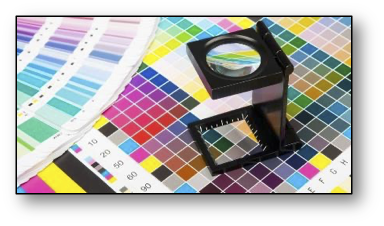

Ink & Color Processes

4-Color Process (CMYK = Cyan, Magenta, Yellow, Black)

- The blending of CMYK color delivers a wide variety of colors for most applications

- May not be consistent in replicating specific colors that are unique to brands

- Economical

PMS/Pantone

- Specifically coded colors for exact visual match

- "Spot" one-off PMS Color can be used in conjunction with CMYK

- PMS colors can cost more

Coating & Finishing Effects

Varnish: Transparent ink, printed inline, dries slow and is the least expensive

Aqueous (AQ): Water based coating, fast drying and environmentally safe

- Cost effective alternative to varnish

Ultraviolet (UV): Highest-gloss & rub resistance, bright, protects ink print/color and the most expensive. Can crack and peel at scores.

Mylar Film: High gloss and durable with protective laminated clear film layer

Reticulation: Coatings/overprint applied after print for effect (Ex Crackled & textured)

Emboss

Stamping (Up) a 'raised' element into the material.

Deboss

Stamping (In) a 'relief' or pressed element into the material.

Foil Stamping/Leafing

Embossing a 'raised' element & laminating a film or foil to result in a 'spot' foil effect.

Hot Stamp

Using heat to deboss/stamp a film or foil material resulting in a 'spot' foil effect.